Company News

Introduction:

In the fast-paced world of manufacturing, efficiency and consistency are paramount. When it comes to packaging a wide variety of products, Side Load Packaging Machine (SLPMs) have become a cornerstone of streamlined production lines. These versatile machines offer a reliable and high-speed solution for enclosing products in carton, ensuring their protection and facilitating efficient distribution.

Performance:

Packing Speed: This refers to the number of cartons the machine can produce per minute.

Max Package Size (L x W x H): This defines the maximum product dimensions the machine can handle.

Operational Features:

Feeding System: Indicate how products are fed into the machine (e.g., manual, automatic feeder).

Date Coding & Printing: Mention if the machine can print dates, logos, or other markings on the carton.

Machine Specifications:

Machine Dimensions (L x W x H): This determines the machine's footprint in your production line.

Power Supply: Specify the voltage and amperage requirements of the machine.

Compressed Air Requirement: Indicate if the machine requires compressed air for operation.

Additional Parameters:

Control System: Mention the type of control panel (e.g., touchscreen, PLC).

Safety Features: Indicate safety features like emergency stops and machine guards.

By understanding these technical parameters, you can choose a Side Load Packaging Machine that meets your specific production needs, product type, and packaging requirements.

Productivity

(box/min)

≤350box/min

Max. carton size

(mm)

160×100×50

Min. carton size

(mm)

65×25×15

Carton quality

250-350/m²

Max. instruction

size (length × Wide)

260×180

Min. specification

size (length × Wide)

110×100

Power Supply

380V 50Hz

Overall dimension

(mm)

5100×1700×180

Weight (kg)

3500

Understanding Side Load Packaging Machines

Side Load Packaging Machines, operate by creating a horizontal around a product. The process typically involves feeding a product into a machine, folding and transfer, box forming, rear push mechanism related technology, the simple design makes the operation and maintenance more convenient.

How it Works:

Here's a breakdown of the typical workflow within a Side Load Packaging Machine:

Product Infeed: Products are fed into the machine using various methods, such as conveyor belts, vibratory feeders, or manual loading depending on the product characteristics and production volume.

Loading and Sealing: The measured product enters the formed carton. The open end of the carton is then sealed using heat sealing or other methods depending.

Date Coding and Printing: Depending on the machine's capabilities, date codes, lot numbers, or other variable information can be printed directly onto the carton.

Product Discharge: The finished, sealed package exits the machine onto a conveyor belt or into a collection bin, ready for further processing or shipment.

Benefits of Side Load Packaging Machines

SLPMs offer a multitude of advantages for manufacturers across various industries:

Increased Efficiency: Automation and high-speed operation significantly improve packaging speed compared to manual methods.

Improved Product Consistency: Precise dosing and carton formation ensure consistent packaging quality and presentation.

Reduced Labor Costs: Automation minimizes the need for manual labor in the packaging process.

Versatility: SLPMs can handle a wide range of products, from food and pharmaceuticals to hardware and consumer goods.

Flexibility: Different carton styles can be used depending on product requirements.

Integration: Many SLPMs can seamlessly integrate with existing production lines.

Considerations When Choosing a Side Load Packaging Machine

Several factors come into play when selecting an SLPM:

Product Characteristics: The size, shape, weight, and fragility of the product will influence the type of machine and its capabilities.

Desired Packaging Format: Products packs and carton style might be required for specific products or marketing purposes.

Production Speed: Match the machine's speed to your desired production volume.

Budget: SLPM s range in price depending on features, complexity, and brand.

The Future of Side Load Packaging Machine

Innovation is constantly pushing the boundaries of SLPM capabilities. Emerging trends include:

Sustainable Packaging: Recyclable materials are becoming increasingly popular options.

Advanced Sealing Technologies: Improved seal integrity ensures product safety and extends shelf life even further.

Vision Systems and Robotics: Integration with vision systems and robots enhances product inspection, handling, and overall automation.

As technology continues to advance, the capabilities of Side Load Packaging Machines are expected to expand. Innovations in automation, artificial intelligence, and machine learning are set to further enhance their efficiency and adaptability. These advancements will likely lead to even more precise and reliable packaging solutions, meeting the evolving demands of various industries.

Conclusion:

In conclusion, Side Load Packaging Machines have become an essential component of modern manufacturing. Their ability to enhance efficiency, ensure product protection, and offer versatility makes them invaluable across a range of industries. As technology progresses, these machines will continue to evolve, driving further improvements in packaging processes and contributing to the overall growth and sustainability of the manufacturing sector.Side Load Packaging Machine-Good Year (Shanghai) Co., Ltd. (goodyearsh.com)

Call us directly at 086-13681729808 or email us at info@goodyearsh.com for any inquiry. You can visit our company at location: T4, No.2, Lane 268, Taihong Road, Minhang District, Shanghai,ChinaIntroduction

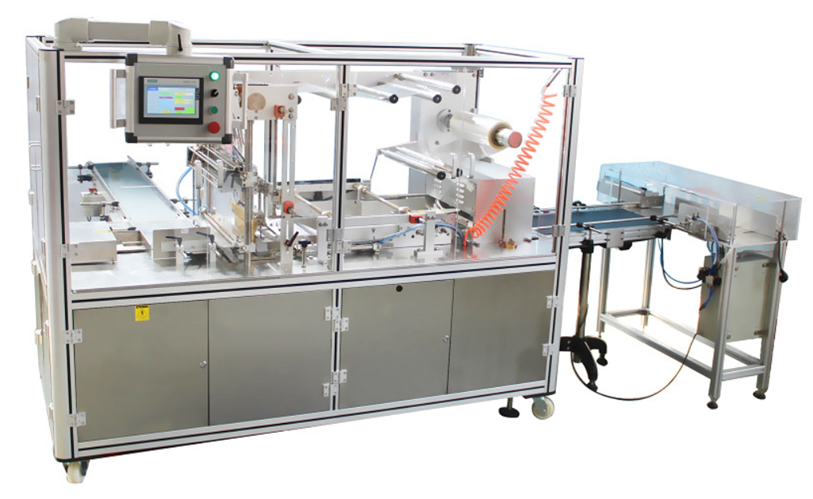

In today's fast-paced industrial environment, efficient and reliable packaging systems are crucial for maintaining product integrity and customer satisfaction. Semi-automatic overwrap machines play a vital role in modern packaging by combining automation's benefits with manual intervention's flexibility. These machines are pivotal in enhancing packaging speed, consistency, and quality across various industries. This essay explores semi-automatic overwrap machines' role, benefits, applications, and impact on the packaging industry.

Overview of Semi-Automatic Overwrap Machines

The Good Year's Semi-automatic overwrap machines are designed to wrap products with a thin layer of plastic film, typically used to secure items, enhance their appearance, and provide protection. The Servo drives provide full control over all machine motions and guarantee perfect product handling. These machines require some level of human involvement for tasks like feeding products into the machine, but they automate the wrapping process itself. The integration of manual and automatic processes allows for a balance between efficiency and adaptability.

Why Good Year Semi-Automatic Overwrap Machines?

Good Year packaging machinery is well-known worldwide for its excellent packaging quality. Continual innovation, together with the constant introduction of improved technology allows us to maintain the high standards demanded in the industry. These machines apply a film layer (usually plastic film) around a product, creating a secure and tamper-evident outer wrap. Unlike fully automatic machines, semi-automatic overwrap machines require some operator intervention, typically for product loading and unloading.

Key Features and Components

Film Roll Holder: Holds the roll of wrapping film and ensures smooth heat sealing.

Cutting Mechanism: Precisely cuts the film to the required length.

Heat Sealing Unit: Seals the film around the product to secure it.

Conveyor System: Transports products through different stages of the wrapping process.

Control Panel: Allows operators to adjust settings and monitor the wrapping process.

Benefits of Semi-Automatic Overwrap Machines

Enhanced Productivity: Semi-automatic overwrap machines significantly increase the speed of the packaging process compared to manual methods. This leads to higher throughput and efficiency, which is crucial for meeting production targets in industries like food, pharmaceuticals, and consumer goods.

Consistency and Quality: Automated wrapping ensures uniform application of the film, leading to consistent quality in packaging. This uniformity enhances product presentation and ensures that each package meets the required standards, reducing the likelihood of customer complaints.

Cost Efficiency: While fully automatic machines may represent a significant investment, semi-automatic machines offer a cost-effective solution with a quicker return on investment. They reduce labor costs and minimize material wastage, which can contribute to substantial savings over time.

Flexibility: These machines can handle various product sizes and shapes with minimal adjustments. This flexibility makes them suitable for small to medium-sized enterprises that need to package different products without investing in multiple machines.

Ease of Use: Semi-automatic overwrap machines are user-friendly, with straightforward controls and easy-to-learn operations. This reduces the need for extensive training and allows for quick adaptation by the workforce.

Applications of Good Year Semi-Automatic Overwrap Machines

Because of their great flexibility, the Good Year over wrappers can be found in many different industries, such as perfumes/cosmetics, pharmaceuticals, tea/coffee, tobacco, confectionery, and foods. These machines cater to a diverse range of industries, including:

Food and Beverage Industry: Semi-automatic overwrap machines are extensively used in the food industry for packaging items like baked goods, confectioneries, and dairy products. The machines help maintain hygiene standards by providing an additional layer of protection against contaminants. Wrapping bakery goods, confectionery items, and pre-packaged meals.

Pharmaceutical Industry: In the pharmaceutical sector, these machines ensure the secure packaging of medicines, protecting them from moisture, dust, and other environmental factors. Consistent wrapping also helps in maintaining the integrity of sensitive products. Securing and protecting pharmaceutical products like boxes and blister packs.

Consumer Goods: For products like cosmetics, electronics, and household items, overwrap machines enhance the visual appeal of the packaging while ensuring product safety during transportation and storage.

Printing and Publishing: Books, magazines, and other printed materials benefit from overwrapping as it protects them from damage and maintains their pristine condition until they reach the consumer. Overwrapping books, notebooks, and other printed materials.

Impact of Semi-Automatic Overwrapping Machines on the Packaging Industry

The integration of semi-automatic overwrapping machines in packaging systems has transformed the industry in several ways:

Increased Efficiency and Output: The combination of automation and manual operation allows companies to significantly boost their production rates. This capability is essential for keeping up with market demand and maintaining a competitive advantage.

Improved Product Protection: The protective layer provided by overwrapping shields products from physical damage, dust, and moisture, which is especially critical for perishable goods and sensitive items.

Enhanced Branding and Marketing: High-quality, consistent packaging enhances the overall brand image and helps in marketing products effectively. Overwrap machines enable companies to present their products attractively and professionally.

Sustainability: Modern overwrap machines are designed to minimize material waste and can often use eco-friendly wrapping films. This focus on sustainability helps companies reduce their environmental footprint and comply with regulatory standards.

Adaptability to Market Trends: As consumer preferences and market trends evolve, semi-automatic overwrap machines offer the flexibility to adapt quickly. Companies can easily switch between different packaging formats and sizes without significant downtime or cost.

Challenges and Considerations

While semi-automatic overwrap machines offer numerous benefits, there are challenges and considerations to address:

Initial Investment: Although more affordable than fully automatic machines, semi-automatic overwrap machines still require a significant initial investment. Companies must evaluate the cost-benefit ratio to ensure it aligns with their production needs and budget.

Maintenance and Downtime: Regular maintenance is essential to keep the machines running smoothly. Companies must establish maintenance schedules and have trained personnel to handle repairs and troubleshooting to minimize downtime.

Training and Skill Development: Operators need to be adequately trained to operate the machines efficiently. Continuous skill development is crucial to keep up with technological advancements and maintain productivity.

Technical Specifications:

Name

Regular

Larger

Specification of machine(mm)

1900(L)×760(W)×1070(H)

2100(L)×800(W)×1070(H)

Packaging dimension(mm)

(L)40-300×(W)20-200×(H)20-80

(L)50-350×(W)30-270×(H)20-100

Packaging speed

6-25cases/min

6-15cases/min

air consumption

18-35L/Min

18-35L/Min

total power

3KW

4KW

voltage

220V/50Hz

220V/50Hz

Weight(about)

150KG

200KG

Conclusion:

The Good Year's Semi-automatic overwrap machines offer a valuable balance between automation and affordability. They provide businesses with a practical solution to enhance their packaging efficiency, consistency, and product presentation. By integrating them into modern packaging systems, manufacturers can achieve faster production cycles, reduce labor costs, and deliver high-quality packaged goods to their customers.

Their role in enhancing productivity, ensuring consistent quality, and adapting to diverse packaging needs makes them a valuable asset across various industries. While challenges exist, the benefits they provide far outweigh the drawbacks, making them a wise investment for companies aiming to optimize their packaging processes. As technology continues to advance, the capabilities of these machines will likely expand, further solidifying their importance in the ever-evolving packaging landscape.Semi-automatic Overwrap Machine-Good Year (Shanghai) Co., Ltd. (goodyearsh.com)

Contact us for quick inquiry at 086-13681729808 or email us at info@goodyearsh.comIntroduction:

Sleeve packing machines are a type of automated packaging equipment used to apply a sleeve of paperboard around products. This creates a secure, tamper-evident, and attractive package that can be used for a wide variety of applications across numerous industries.

Sleeve packing machines have become a cornerstone of modern packaging solutions, offering a fast, secure, and visually appealing way to bundle and protect products. But beyond their undeniable benefits, these machines boast a range of operational features and parameters that determine their effectiveness. Understanding these intricacies is crucial for getting the most out of your sleeve packing operation.

How Sleeve Packing Machines Work:

The basic operation of a sleeve-packing machine involves the following steps:

Product Infeed: Products are fed automatically or manually into the machine.

Sleeve Forming: A pre-cut paperboard is placed or formed around the product.

Sealing: The open ends of the sleeve are sealed together using hot glue.

Outfeed: The finished, packaged product exits the machine.

Benefits of Sleeve Packing Machines:

Sleeve packing machines offer several advantages over traditional packaging methods:

Increased Efficiency: Automation streamlines the packaging process, leading to faster production speeds and reduced labor costs.

Improved Product Presentation: Sleeve packaging creates a clean, professional, and eye-catching presentation that enhances product appeal on store shelves.

Enhanced Tamper Evident Security: Shrink sleeves become difficult to tamper with once shrunk, offering a layer of security against product tampering.

Protection: Both shrink sleeves and paperboard sleeves offer some level of protection against dust, moisture, and scratches.

When selecting a Sleeve Packing Machine consider the Following Factors:

Product Type and Size: Choose a machine that can handle the size, shape, and weight of your products.

Production Speed: Select a machine with a speed that meets your production requirements.

Level of Automation: fully automatic systems.

Sleeve Material: Consider paperboard sleeves are more suitable for your application.

Budget: Sleeve packing machines range in price depending on features and capabilities.

Additional Considerations:

Machine Footprint: Ensure the machine has the appropriate footprint for your available space.

Ease of Use and Maintenance: Choose a machine with user-friendly controls and easy maintenance procedures.

By carefully considering these factors, you can select a sleeve packing machine that optimizes your packaging process, enhances product presentation, and meets your specific production needs.

Operational Features:

Modern sleeve packing machines go beyond these core functionalities by offering a variety of features that enhance efficiency and cater to specific packaging needs. Some key features include:

Machine Speed and Capacity: Machines vary in speed, typically measured in packs per minute. This is crucial when considering production volume requirements.

Product Size Range: The machine's design determines the size and shape of products it can handle.

Infeed and Outfeed Systems: Integration with conveyors or other automated systems ensures smooth product flow.

Changeover Flexibility: Easy adjustment of settings and tooling allows for quick transitions between different product sizes or sleeve types.

Human-Machine Interface (HMI): Intuitive control panels allow for easy operation and monitoring of machine parameters.

Safety Features: Safety features like emergency stops and guards are essential for operator protection.

Sleeve Packing Machine Compatibility:

Please note: Sleeve packing machines come in various sizes and capabilities. This table provides a general guideline. Always consult the specific machine's manual for confirmed dimensions and weight limitations.

Productivity

(box/min)

≤60box/min

Max. carton size

(mm)

160×80×30

Min. carton size

(mm)

90×80×15

Carton quality

250-350/m²

Max. instruction

size (length × Wide)

260×180

Min. specification

size (length × Wide)

110×100

Instruction

quality

55-65/m²

Power Supply

380V 50Hz

Overall dimension

(mm)

6100×1200×1800

Weight (kg)

3200

Conclusion:

Sleeve packing machines offer a powerful and versatile packaging solution. By understanding their operational features and parameters, you can optimize your process for efficiency, product protection, and a visually appealing outcome. From selecting the right features for your specific needs to fine-tuning operational parameters, you can ensure your sleeve packing machine delivers maximum value for your business.Sleeve Packing Machine-Good Year (Shanghai) Co., Ltd. (goodyearsh.com)

Call us directly at 086-13681729808 or email us at info@goodyearsh.com for any inquiry. You can visit our company at location: T4, No.2, Lane 268, Taihong Road, Minhang District, Shanghai,ChinaThe rotation overwrap machine, a workhorse in the packaging industry, efficiently secures products with a layer of plastic film. This article delves into the intricate workings of this machine, exploring its components, operation, and the features it offers. Good Year packaging machinery is well-known worldwide for its excellent packaging quality. Continual innovation, together with the constant introduction of improved technology allows us to maintain the high standards demanded in the industry.

Because of their great flexibility, the Good Year over wrappers can be found in many different industries, such as perfumes/cosmetics, pharmaceuticals, tea/coffee, tobacco, confectionery, and foods.

When selecting a rotation overwrap machine, consider the following factors:

Product Type and Size: Ensure the machine can handle your product dimensions and weight.

Production Speed Requirements: Choose a machine that meets your desired output.

Film Compatibility: Select a machine compatible with your preferred film type.

Desired Features: Determine if additional features like a shrink tunnel or label application are necessary.

Budget: Consider the initial and long-term cost of the machine.

By carefully evaluating your needs and these features and parameters, you can select the ideal rotation overwrap machine to streamline your packaging process and ensure product security.

Features & Parameters of Rotating Overwrap Machine

A rotation overwrap machine is an automated packaging system that utilizes a rotating platform to securely wrap products in film. These machines are ideal for high-speed applications and offer a tamper-evident seal for various product types. Here's a breakdown of their key features and parameters:

Feature:

Rotating Platform: This is the heart of the machine and allows products to be fed, wrapped, and sealed while constantly rotating. Different configurations exist, including single turntable for increased throughput.

Film Feeding System: The machine dispenses film from a roll, typically held on a powered unwind stand. Tension control ensures a smooth and consistent film application.

Film Sealing System: Heat sealers or cold seal systems create a secure closure on the film. Heat sealers utilize bars or impulse seals, while cold seal systems rely on adhesives pre-applied to the film.

Film Cutting System: A cutting mechanism severs the film after each product is wrapped. Options include shears, hot knives, or ultrasonic cutters depending on the film type.

Product Infeed and Outfeed Systems: These systems transport products onto and off the rotating platform. Depending on the application, they could be conveyor belts, pushers, or robotic arms.

Control Panel: This interface allows for setting parameters like film tension, seal temperature/time, and wrapping speed. Modern machines offer user-friendly interfaces and recipe storage for various product types.

Safety Features: Safety features are crucial, including emergency stops, light curtains, and guards to prevent operator injury.

Shrink Tunnel: A heated tunnel shrinks the film around the product for a tighter and more tamper-evident seal.

Product Indexing System: Ensures products are positioned correctly for wrapping and sealing.

Data Acquisition System: Tracks production data like cycle times, product count, and potential issues.

Remote Monitoring: Allows for monitoring and adjustment of machine parameters remotely.

Enhanced Product Protection: The overwrap film provides a barrier against dust, moisture, and contamination, extending product shelf life.

Improved Tamper Evident Security: The sealed film provides a visual and functional deterrent against tampering.

Branding and Marketing: Printed film can display product information, logos, and promotional messages.

Parameters:

Machine Speed: This refers to the number of cycles (products wrapped) per minute.

Product Size Range: The dimensions (length, width, height) of products the machine can accommodate.

Film Type and Width: The type of film compatible with the machine (e.g., BOPP) and the maximum film width it can handle.

Seal Length and Strength: The length and strength (measured in pounds per square inch) of the film seal.

Film Tension: The amount of tension applied to the film during wrapping, affects product presentation and seal quality.

Seal Temperature and Time: For heat sealers, these parameters determine the effectiveness of the seal without damaging the film.

Infeed and Outfeed Conveyor Speeds: The speed of conveyors feeding and exiting products from the machine.

Components of Rotation Overwrap Machine:

Infeed Conveyor: This conveyor belt continuously feeds products into the machine at a controlled speed.

Turntable: This rotating platform receives the products from the infeed conveyor, it allows the film to be applied uniformly around the product.

Film Feeders: This unit houses a roll of film and dispenses it precisely onto the turntable.

Film Sealing System: Heating plate press the film together, creating a strong seal.

Outfeed Conveyor: The finished product exits the machine on this conveyor, ready for further processing or palletization.

Control Panel: This user interface allows for setting parameters like sealing temperature and machine speed, etc.

Rotation Overwrap Machine Technical Details

Speed

40-80Box/min

Package Size

(L)80-400 x (W)45-240 x (H)20-120mm

Machine Size

(L)2180 x (W)1000 x (H)1500mm

Feeding Conveyor Size

(L)1600 x (W)270 x (H)770mm

Air pressure

0.6-0.7Mpa

Power

4.5KW

Voltage

3 x 380V+N+PE

Weight(Aproximate)

800Kg

Conclusion:

The rotation overwrap machine is a versatile and efficient packaging solution. With its ability to protect, bundle, and brand products, it plays a vital role in various industries. Understanding its components, operation, and benefits allows businesses to choose the right machine for their specific needs and gain an edge in the competitive packaging landscape.

If you're looking for further information, consider searching for specific models of rotation overwrap machines from reputable manufacturers. This will provide detailed specifications and capabilities to help refine your decision.

Rotation Overwrap Machine-Good Year (Shanghai) Co., Ltd. (goodyearsh.com)

Introduction:

A vertical packing machine (VPM) is an automatic packaging equipment designed to package products into a carton in a vertical orientation. These machines perform several functions, including sorting products, counting in the group and loading the products into cartons through vertical way. This seamless integration of processes enhances productivity and reduces labor costs. They offer a versatile and efficient solution for packaging a wide range of products, making them popular across various industries.

One significant innovation that has revolutionized the packaging industry is the vertical packing machine (VPM). Due to their versatility, speed, and reliability, these machines have become indispensable in various sectors, from food and beverage to pharmaceuticals.

Technical Specifications:

Here's a glimpse into some of the key technical parameters of vertical packing machines:

Machine Speed: Measured in cartons per minute (BPM), this indicates the machine's output. Speeds range from 20 BPM for complex fills to over 150 BPM for simple applications.

Productivity

(box/min)

≤80box/min

Max. carton size

(mm)

150×100×200

Min. carton size

(mm)

35×25×45

Carton quality

250-350/m²

Max. instruction

size (length × Wide)

260×180

Min. specification

size (length × Wide)

110×100

Overall dimension

(mm)

3850×2000×1900

Weight (kg)

2300

Key Features and Functions:

Vertical packing machines boast several features that make them ideal for a wide range of applications:

Versatility: VPMs can handle a variety of products, including solids, liquids, powders, and granules. This makes them suitable for industries such as food processing, pharmaceuticals, cosmetics, and chemicals.

High Speed and Efficiency: These machines can produce hundreds of packages per minute, significantly boosting production rates. This high-speed operation is essential for meeting the demands of large-scale production facilities.

Compact Design: The vertical orientation of these machines saves valuable floor space, making them suitable for facilities with limited space.

Ease of Use and Maintenance: Modern VPMs come with user-friendly interfaces and require minimal maintenance, reducing downtime and operational costs.

Modern vertical packing machines are equipped with advanced features for user-friendly operation and efficient production. These can include:

Touchscreen HMI (Human Machine Interface): Provides intuitive control over machine settings and operation.

Programmable Logic Controller (PLC): Allows for recipe storage and automatic control of filling parameters.

Date/Lot Coding: Integrates printing systems to mark cartons with production information.

Safety Systems: Ensures safe operation with features like emergency stops and machine guards.

By understanding these technical parameters and features, you can select a vertical packing machine that best suits your specific packaging needs.

Applications in Various Industries:

Food and Beverage: The food industry extensively uses VPMs for packaging snacks, coffee, spices, sauces, and frozen foods. The ability to handle different types of packaging materials, allows manufacturers to choose the best option for product preservation and presentation.

Pharmaceuticals: In the pharmaceutical industry, VPMs are used to package tablets, capsules, powders, and liquids. It protects products and enables them to be transported, stored and used in a safe manner.

Cosmetics and Personal Care: VPMs are employed to package products like creams, lotions, shampoos, and gels. The machines’ ability to handle various products and packaging formats helps maintain the integrity and appeal of these products.

Technological Advancements:

The evolution of vertical packing machines has been marked by significant technological advancements. Modern VPMs incorporate sophisticated features such as:

Automation and Integration: Advanced VPMs are equipped with automation systems that integrate with other production line equipment, such as conveyors, labeling machines, and quality control systems. This integration streamlines the packaging process and enhances overall efficiency.

Touchscreen Controls: User-friendly touchscreen interfaces allow operators to easily set parameters, monitor performance, and diagnose issues, further reducing downtime.

Enhanced Safety Features: Modern VPMs come with advanced safety features, including sensors and interlocks, to protect operators and ensure safe operation. These features are particularly important in industries handling hazardous materials.

Economic and Environmental Impact:

The adoption of vertical packing machines has significant economic and environmental implications:

Cost Reduction: By automating the packaging process, VPMs reduce labor costs and minimize product waste, leading to substantial cost savings for manufacturers.

Increased Production Capacity: The high-speed operation of VPMs allows manufacturers to increase their production capacity, meet market demand, and expand their market presence.

Sustainability: The ability to use sustainable packaging materials and reduce waste aligns with global efforts to minimize environmental impact. VPMs contribute to the reduction of plastic waste and the promotion of recycling initiatives.

Future Trends:

The future of vertical packing machines with ongoing advancements in automation, artificial intelligence, and sustainable packaging solutions. As industries continue to evolve and consumer preferences shift, VPMs will play a crucial role in meeting the demand for efficient, precise, and eco-friendly packaging solutions.

Conclusion:

In conclusion, vertical packing machines have transformed the packaging industry by offering versatile, efficient, and reliable solutions for a wide range of products. Their continued evolution and integration of cutting-edge technologies ensure that they will remain a cornerstone of modern manufacturing and packaging processes.Vertical Packing Machine-Good Year (Shanghai) Co., Ltd. (goodyearsh.com)

Call us directly at 086-13681729808 or email us at info@goodyearsh.com for any inquiry. You can visit our company at location: T4, No.2, Lane 268, Taihong Road, Minhang District, Shanghai,China

Introduction

Good Year, a leading manufacturer of packaging solutions, is constantly innovating to meet the evolving needs of its customers. As we approach 2024, sustainability, enhanced performance, machine versatility, and smart technologies are expected to be at the forefront of horizontal overwrap machine development.

What is a Horizontal Overwrap Machine?

A horizontal overwrap machine is an automated packaging system that wraps products in film. Products are fed onto a conveyor and then wrapped in film as they pass through a sealing system. These machines are commonly used for Three-dimensional wrapping on the outside of the product to guarantee the integrity of the product during sales and transportation.

Benefits of Horizontal Overwrap Machines:

Increased Efficiency: Automates the wrapping process, saving time and labor costs.

Improved Product Protection: Wrapping protects products from dust, moisture, and damage during transport.

Enhanced Tamper Evident Packaging: Seals can be designed to deter tampering.

Standardization: Ensures consistent wrapping quality for all products.

Technical Specifications:

Speed

15-45Box/min

Size

(L)80-380mm(W)45-240mm(H)20-90mm

Machine Size

(L)2180mm(W)1000mm(H)1500mm

Feed Conveyor

(L)1600mm(W)270mm(H)770mm

Weight(Around)

800Kg

Power

6.5Kw

Voltage

3X380V+N+PE

Air Pressure

0.6-0.7Mpa

Potential Developments in Horizontal Overwrap Machines:

Sustainable Packaging: Integration of recyclable or biodegradable films for eco-friendly packaging.

Smart Machines: Utilizing sensors and data analytics for optimizing film usage, maintenance, and performance.

Increased Automation: Integration with robotic systems for fully automated palletizing and wrapping processes.

Based on current packaging industry trends and Good Year's existing technology,

Here's a glimpse

• Focus on Sustainability

Recyclable Materials: Machines designed to use less film or incorporate a higher percentage of recycled content in wraps.

Energy Efficiency: Developments to reduce the machine's overall energy consumption.

Biodegradable Films: Exploration of bio-based films for wrapping applications.

• Enhanced Machine Performance

Improved Film Sealing Technology: Stronger, more reliable seals to reduce leaks and product spoilage.

Increased Automation and Integration: Integration with existing conveyor systems and automated loading/unloading for higher throughput.

Advanced Diagnostics and Predictive Maintenance: Built-in sensors to monitor machine performance and predict potential issues for proactive maintenance.

• Machine Versatility

Multi-format Packaging: Ability to handle products of different shapes and sizes efficiently.

Tooling Customization: Options for easy customization to accommodate specific product packaging needs.

• Smart Technologies

Remote Monitoring and Control: Ability to monitor machine performance and make adjustments remotely for improved efficiency.

Data-driven Insights: Machines that generate data on film usage, machine performance, and potential maintenance needs.

• Sustainability – The Driving Force

In an era of growing environmental concerns, sustainability will undoubtedly be a major focus for Good Year. We can expect to see machines designed to use less film, potentially with features like film pre-stretching or down-gauging technology. Additionally, the company might explore the use of a higher percentage of recycled content in the films themselves or even develop machines compatible with biodegradable bioplastic films.

Good Year's commitment to sustainability might extend to energy efficiency as well. Machines could be equipped with features like variable speed drives, optimized heating systems, and even regenerative braking to reduce overall energy consumption.

Enhanced Performance for Increased Efficiency

Good Year machines are known for their reliability and performance. In 2024, we might see further advancements in this area. Improved sealing technology using stronger welds or innovative sealing methods could minimize leaks and product spoilage.

Automation is another area ripe for development. Machines could seamlessly integrate with existing conveyor systems for automatic product loading and unloading, significantly increasing throughput. Additionally, features like automatic film loading and roll splicing could further streamline the packaging process.

Predictive maintenance will likely play a bigger role as well. Sensors embedded within the machines could monitor critical parameters like motor temperature, bearing vibrations, and film tension. By analyzing this data, the machine could predict potential issues and alert operators for proactive maintenance, minimizing downtime.

Machine Versatility – Catering to Diverse Needs

The packaging industry caters to a wide range of products with varying shapes and sizes. To address this diversity, Good Year's 2024 machines might offer increased versatility.

This would allow manufacturers to choose the optimal film thickness for each product, balancing cost with the required level of protection. Additionally, the machines could be designed to handle products of different shapes and sizes efficiently, specification parts or specific parameters can be quickly replaced.

Smart Technologies – Ushering in a New Era

Remote monitoring and control could be another game-changer. Operators might be able to monitor machine performance, diagnose issues, and even make adjustments remotely using a secure internet connection. This would allow for improved overall production efficiency.

Finally, data-driven insights could become a valuable tool for manufacturers. Machines equipped with sensors could generate data on film usage, machine performance, and potential maintenance needs. This data could be analyzed to identify areas for improvement, optimize production processes, and reduce costs.

Conclusion:

If you're looking for further information, consider searching for specific models of horizontal overwrap machines from reputable manufacturers. This will provide detailed specifications and capabilities to help refine your decision.Horizontal Overwrap Machine-Good Year (Shanghai) Co., Ltd. (goodyearsh.com)

Call us directly at 086-13681729808 or email us at info@goodyearsh.com for any inquiry. You can visit our company at location: T4, No.2, Lane 268, Taihong Road, Minhang District, Shanghai,China

English

English 中文

中文 العربية

العربية Русский язык

Русский язык